- Home

-

Products

-

HF Series RFID Products

-

HF Integrated Reader

-

Product Model

- SG-HR-I1 HF Integrated Reader SG-HR-I2 HF Integrated Reader SG-HR-I5 HF Integrated Reader SG-HR-I6 HF Integrated Reader SG-HR-I10 HF Integrated Reader

-

HF Split Read-write Processor/Split Antenna

-

Product Model

- SG-HA-181/182 HF RFID ANTENNA SG-HA-183 HF Middle Range RFID Reader SG-HR-S1 Universal Fixed RFID Reader SG-HR-S6 Series SG-HR-S8 Series

-

Product Model

-

UHF Series RFID Products

-

UHF Integrated Reader

-

Product Model

- SG-UR-I81 UHF Integrated Reader SG-UR-I82 UHF Integrated Reader SG-UR-I83 UHF Integrated Reader SG-UR-I84 UHF Integrated Reader SG-UR-I85 UHF Integrated Reader SG-UR-I86 UHF Integrated Reader

-

UHF Split Read-write Processor/Split Antenna

-

Product Model

- SG-UR-A9 UHF Split Reader SG-UR-A10 Multi-Channel UHF Read/Write Devices(860~960MHz) SG-UR-A12 Multi-Channel UHF Read/Write Devices(860~928MHz) SG-UR-A16 Multi-Channel UHF Read/Write Devices(860~928MHz) SG-UA-271 UHF Small Universal Antenna UHF Antenna SG-UA-273 UHF Antenna SG-UA-274

-

Product Model

- Industrial Bus Gateway Module

- Industrial Code Reader

-

HF Series RFID Products

- Equipment

- Industry & Case

- News

- Service

- Company

- Details

Product Profile

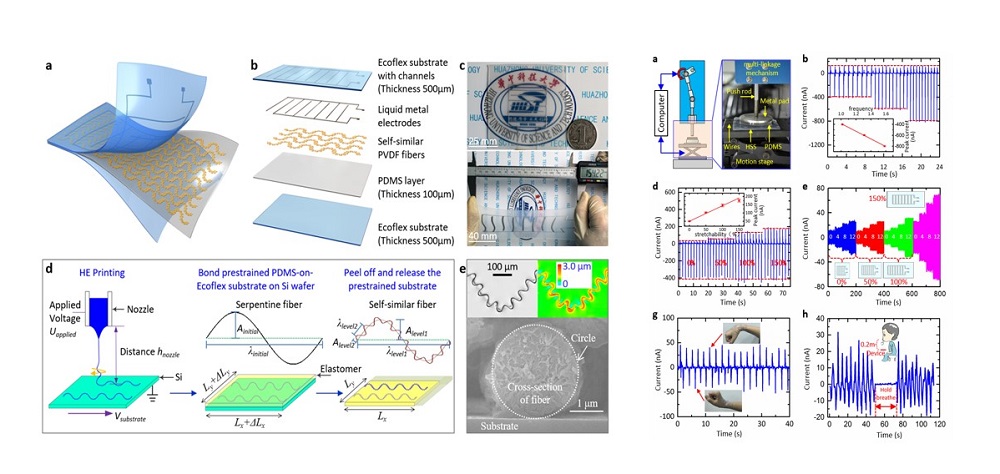

● EHDJet series electrohydrodynamic printing equipment, derived from the original high-resolution electrojet printing technology of the State Key Laboratory of Digital Manufacturing Equipment and Technology of Huazhong University of Science and Technology, won the first prize of the 2017 Natural Science Award of Hubei Province and the invention of the International Geneva in 2014 Exhibition Gold Award; using electrohydrodynamic principles (EHD), equipped with high-speed vision system, high-precision multi-freedom motion platform, precision ink supply system and other functional modules, process resolution: spot spray diameter <1μm, spinning line width <1μm 、Atomized film thickness ~50nm, suitable for organic/inorganic ink with viscosity of 1-10000cPs, integrated three printing modes: dot-on-demand dot printing, spin-on direct writing, atomized film making, support graphic input such as vector and bitmap, high Precise preparation of complex micro-nano patterns such as micro/nano dots/lattices, lines/curves, thin film structures, etc. in many fields such as flexible electronic devices, flexible touch screens, flexible sign patches, solar thin film batteries, flexible sensors, biological scaffolds, tissue engineering , Organic light-emitting diodes, biosensors and other fields have been successfully applied, is the first choice for flexible printing, provides a cost-effective electronic jet printing platform, to help display / materials / energy / biology and other fields of scientific research and application.

Product Advantages

· Flexible electronic patterning-the advantages of inkjet printing technology

· EHDJet electrofluid jet printing prepares stretchable electrons, directly prepares PVDF secondary corrugated fiber, and the device's stretching capacity is increased to 320%.

· EHDJet current body jet printing prepares various two-dimensional structures, using current body spot spraying, spinning, atomization to directly prepare dots, lines/curves, and film structures.

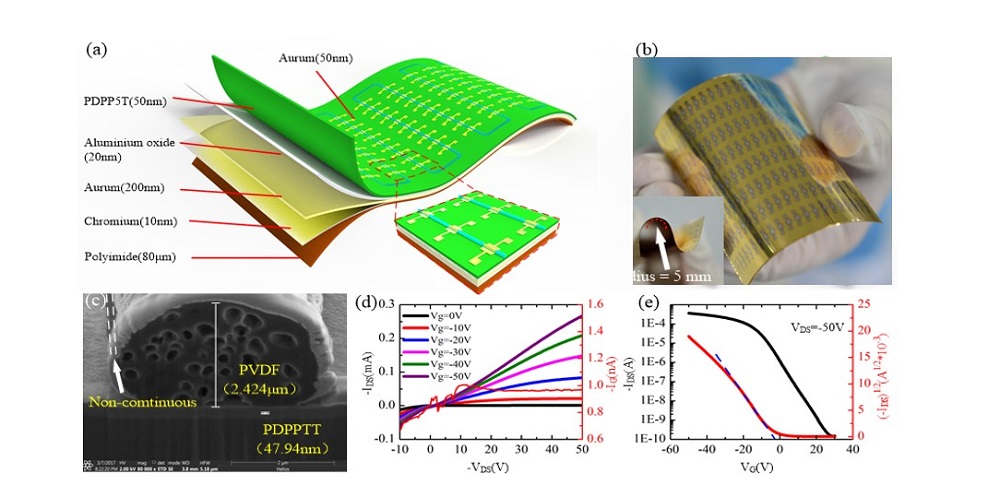

· Thin film transistor TFT-EHDJet current body lithography technology, current body printing photoresist solution, preparation of micro-nano mask pattern, compatible with photolithography patterning process.

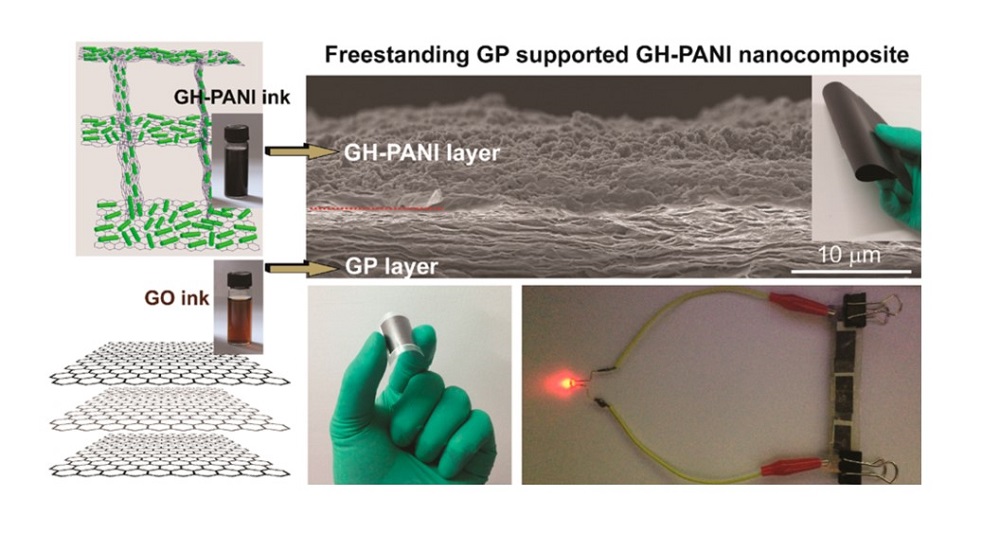

· EHDJet electro-atomizes graphene film, prepares film capacitors, electro-atomization produces fL-level uniform fog droplets, and prepares uniform and dense graphene film.

· EHDJet electrospray printing DNA, fiber scaffold, etc., electrofluid jet printing is suitable for a wide range of ink, can directly print DNA/three-dimensional PLGA/PCL cell scaffold

Application Customers

Technical Parameters

Model | EHDJet-P:Professional micro-nano patterning platform |

Features | All-in-one machine, professional-grade platform, customizable |

Ink supply system | Precision air pressure + flow pump + melt electrospinning three ink supply |

High voltage power supply | ±5000V@Arbitrary waveform editing |

Print frequency | 0~10000Hz |

Print abutment | 210×210mm2(support customization),Vac-sorb, Substrate heating: room temperature~100℃ adjustable and controllable |

Print speed | 3DOF movement, X/Y axis printing speed 0-500mm/s, Z axis speed ≤50mm/S |

Positioning/repeat accuracy | ±3μm / ±1μm |

Visual system | High magnification observation camera+positioning camera |

Picture Format | Support vector graphics, bitmaps, built-in basic primitives (EHDJet-P supports micro-curved printing) |

Process index | The minimum diameter of spot spray <1μm, the minimum line width of wire bonding <1μm, the minimum thickness of film formation ~50nm |