- Home

-

Products

-

HF Series RFID Products

-

HF Integrated Reader

-

Product Model

- SG-HR-I1 HF Integrated Reader SG-HR-I2 HF Integrated Reader SG-HR-I5 HF Integrated Reader SG-HR-I6 HF Integrated Reader SG-HR-I10 HF Integrated Reader

-

HF Split Read-write Processor/Split Antenna

-

Product Model

- SG-HA-181/182 HF RFID ANTENNA SG-HA-183 HF Middle Range RFID Reader SG-HR-S1 Universal Fixed RFID Reader SG-HR-S6 Series SG-HR-S8 Series

-

Product Model

-

UHF Series RFID Products

-

UHF Integrated Reader

-

Product Model

- SG-UR-I81 UHF Integrated Reader SG-UR-I82 UHF Integrated Reader SG-UR-I83 UHF Integrated Reader SG-UR-I84 UHF Integrated Reader SG-UR-I85 UHF Integrated Reader SG-UR-I86 UHF Integrated Reader

-

UHF Split Read-write Processor/Split Antenna

-

Product Model

- SG-UR-A9 UHF Split Reader SG-UR-A10 Multi-Channel UHF Read/Write Devices(860~960MHz) SG-UR-A12 Multi-Channel UHF Read/Write Devices(860~928MHz) SG-UR-A16 Multi-Channel UHF Read/Write Devices(860~928MHz) SG-UA-271 UHF Small Universal Antenna UHF Antenna SG-UA-273 UHF Antenna SG-UA-274

-

Product Model

- Industrial Bus Gateway Module

- Industrial Code Reader

-

HF Series RFID Products

- Equipment

- Industry & Case

- News

- Service

- Company

- Details

Product Profile:

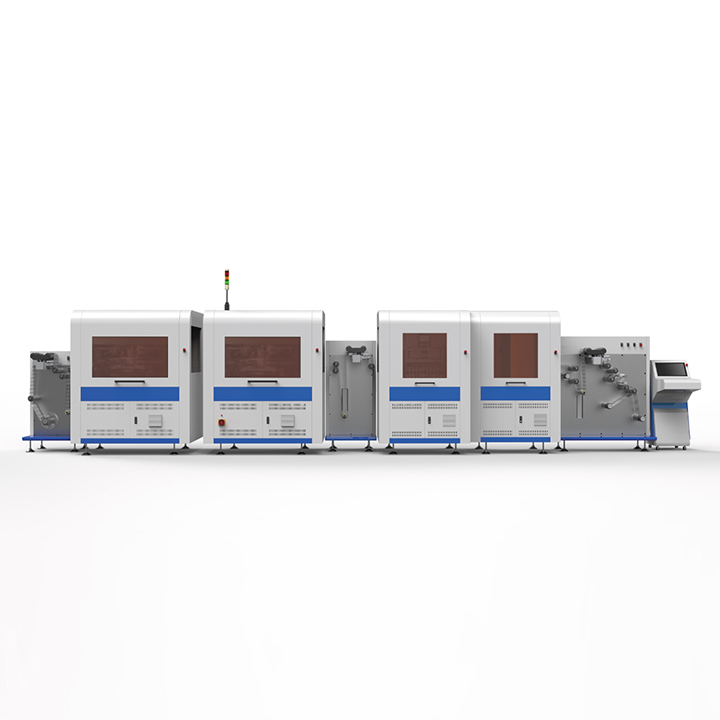

The HEI-DVI type RFID tag packaging equipment adopts a flip-chip bonding process. After the chip is removed from the Wafer disk, it is turned 180° and attached to the antenna substrate, and the Inlay packaging is achieved by the hot press curing of the anisotropic conductive adhesive. The whole machine integrates dispensing, placement, hot-press curing, on-line detection, substrate conveying, rewinding and unwinding modules, which is suitable for efficient packaging of various HF/UHF RFID Inlays.

Specifications

Item | 具体内容 |

SMT efficiency | Max 10000UPH |

Yield | ≥99.5%(HF/UHF) |

Adapt to base material | PET, PI, Paper |

Tag type | HF/UHF |

Antenna form | Copper and aluminum etched antenna, conductive silver paste printedantenna |

Wafer size | 6/8/12 inch |

Chip size | 0.30*0.30—2*5mm² |

Average power consumption | 2KW |

SMT Precision | ±20µm |

Device size | 8000*1400*2400(mm) |

Features

Ø High-precision dispensing technology: the size and thickness of the glue droplets are uniform, with the function of dispensing height compensation and glue volume adjustment

Ø Multi-size specification film taking: equipped with multiple thimble device, suitable for multi-size specification chip taking, the adaptable range is 0.3×0.3—2mm×5mm

Ø High-precision placement scheme: each chip is visually corrected to improve placement accuracy and corner accuracy. Adopt flight vision positioning technology to ensure the placement accuracy is within ±20μm

Ø Excellent performance of hot and hot indenter: with independent patented technology, the indenter surface flatness rate is 0.8 microns/1 mm, the force control accuracy is ±0.1N, and the temperature control accuracy is ±1℃, which provides a reliable guarantee for the consistency of UHF label product performance

Ø Customized detection module: In addition to supporting conventional UHF ISO 18000-6C, and HF ISO 14443, 15693 protocols, it can achieve mass production of national standard GB/29768; and has a customized code writing function, which can be used for INLAY or RFID Electronic tags are used for online code writing, and provide an abnormal code writing alarm function to fully meet customer needs; optional label performance online detection, UHF product sensitivity consistent performance guaranteed within 2dbm.

Ø Integrated online slitting function: it can slit wide Inlay into multiple strips, and after the slitting, the Inlay is rolled up, and the liner is added before the Inlay is received.

Ø Multi-screen display (dual display, one touch screen), user-friendly operation interface and touch operation, split-screen image display, effectively improve the comfort of workers' observation and operation experience.

Ø The key parts of the equipment are supported by the marble platform, which has the advantages of high strength, strong hardness, no rust, good corrosion resistance, strong wear resistance and good shock absorption performance, which effectively guarantees the accuracy of the glue placement.

Advancement of equipment technology

Ø Invented a method and device for positioning based on flight vision. By optimizing the hardware configuration of the vision system and improving the efficiency of software calculation, the positioning time of the tiny chip was shortened to less than 15 milliseconds, which greatly increased the equipment capacity.

Ø Proposed a fast and accurate processing method for dynamic collection of flight vision images, which solves the problems of mixed noise interference, motion/defocus blur, and missing images

Ø Realization of micro-chip rotation attitude correction algorithm: by re-establishing the angle-deviation model and designing a brand-new correction algorithm, the placement accuracy of the micro chip is greatly improved, up to ±15μm

Ø The precise cooperative control of time, pressure and temperature during the breakthrough flip-chip bonding process and the multi-physical quantity precise control system software developed to provide guarantee for the implementation of the label production process

Ø Using EtherCat bus technology, the communication rate is 100M, which ensures real-time communication between the controller and the motor shaft and on-site I/O, improving the efficiency and accuracy of equipment operation

Ø Adopting EtherCat bus technology, greatly reducing the connection between the controller and the motor shaft and on-site I/O, greatly reducing the probability of line failure, and improving equipment stability

Performance of UHF tags produced by equipment

Ø The picture above shows the results of the sensitivity test of the UHF 9662 random inspection. The consistency deviation is within 2dbm, and the equipment and sensitivity yield are above 99.5%

Ø Avoid chip damage, ensure the quality of electronic tag packaging, and greatly improve the qualification rate and production capacity of tag packaging

Ø Improve the quality of domestic RFID tag inverted packaging equipment to ensure tag packaging accuracy, stability, reliability and consistency

Ø Lay a solid foundation for fully replacing imported equipment and creating a national brand of smart equipment